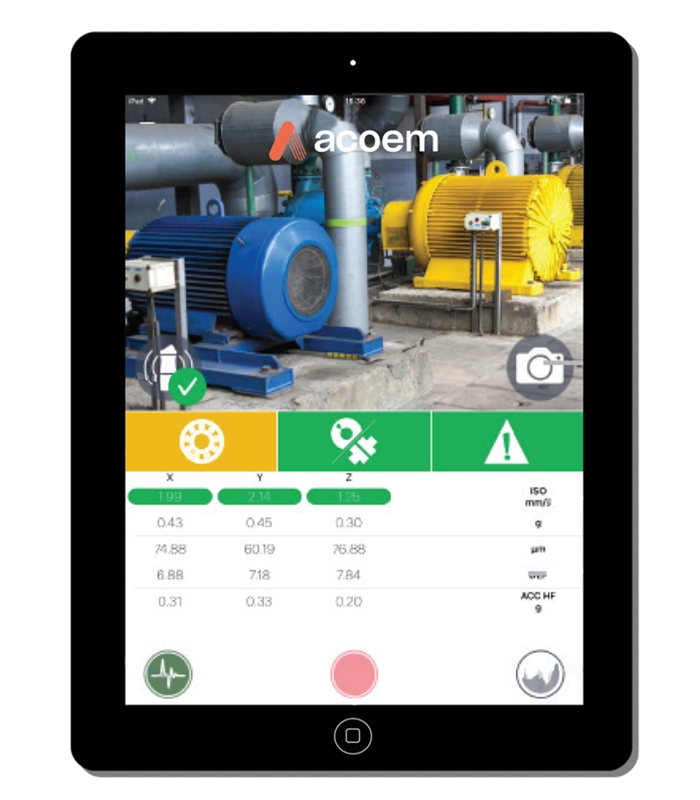

Acoem MV-x: Black Edition

Predictive maintenance powered by artificial intelligence (AI)

Acoem brings to you MV-x Black edition ,the next generation of AI-enabled vibrational analysis, with real-time edge computing, provides a pathbreaking predictive tool to pinpoint the source, direction, and intensity of the vibration. It represents a fundamental shift from reactive maintenance to predictive maintenance. More importantly, it provides vibration analysis and condition monitoring users, with a seamless industry 4.0 experience.

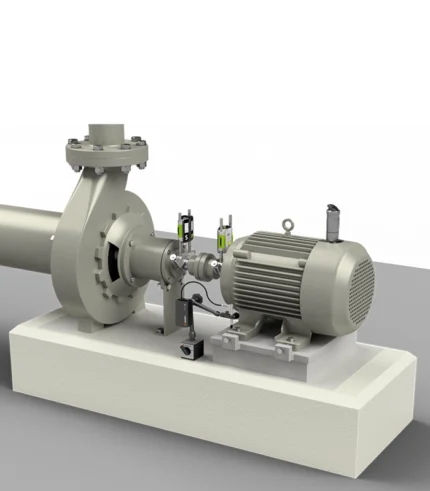

Maximise the reliability of your critical rotating assets

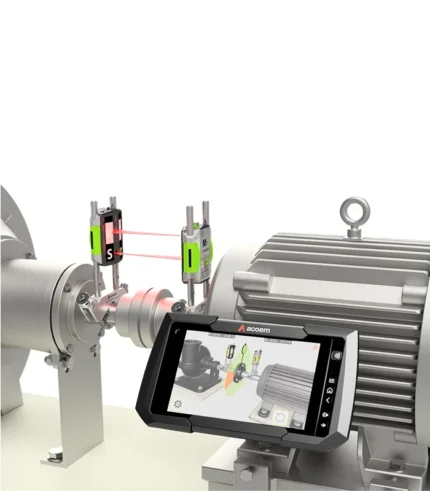

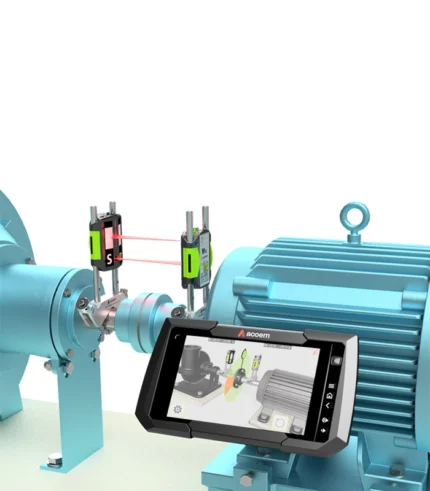

Predictive or condition-based maintenance is a proactive maintenance strategy that allows you to monitor the performance and condition of your machinery in real time. Doing so will enable you to enhance machine reliability and accurately predict when your equipment needs to be maintained —rather than waiting for it to fail. Using a combination of wired or wireless sensors, Internet of Things (IoT), augmented mechanics, machine learning and data analytics, Acoem’s predictive maintenance tools portfolio will help your business anticipate problems before they occur. Schedule maintenance activities at the right time, receive alerts for potential issues with a degree of certainty and enhance your overall industrial productivity.

Reviews

There are no reviews yet.