Sparrow

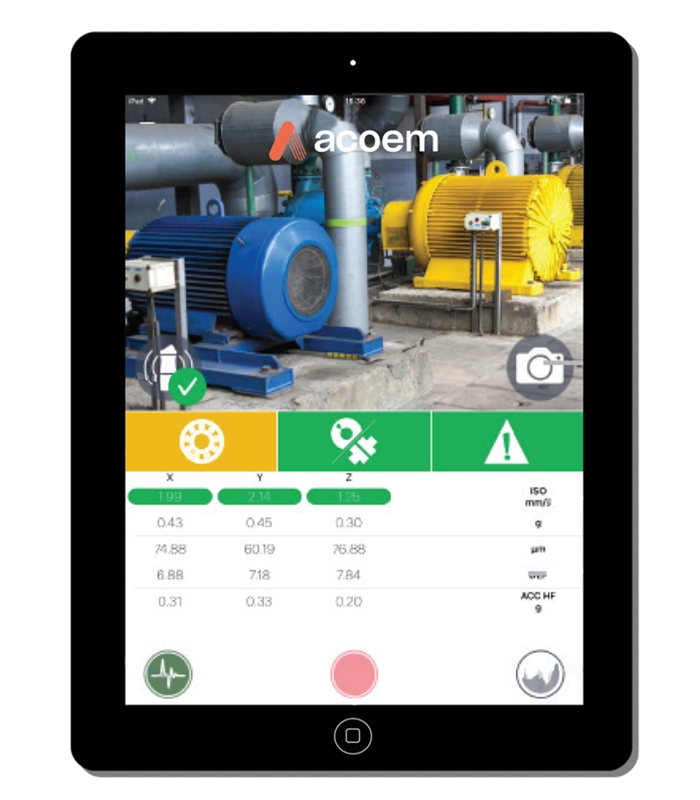

Advanced wireless diagnostics for balance-of-plant assets

Because every asset counts, we are now introducing Sparrow, the smallest wireless triaxial vibration and temperature sensor on the market with no new software to install and learn, no additional training and no need to take the focus away from your critical machinery.

Its capabilities, affordability and full integration with our Nesti4.0 software platform make it the perfect choice for monitoring every balance-of-plant asset in your facility and the ideal complementary sensor to your existing network of Acoem critical asset solutions like the Eagle or MV-x.

Datasheets

Spparrow-Datasheet.pdf Sparrow-Brochure.pdf

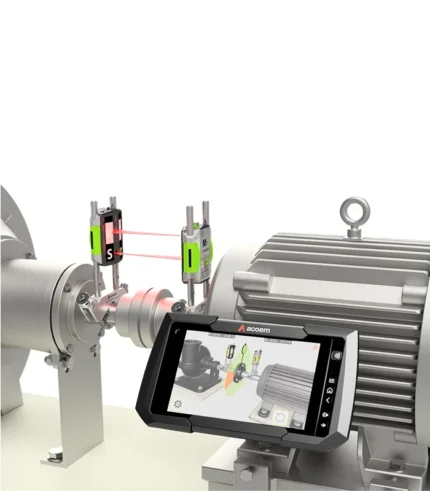

Maximise the reliability of your critical rotating assets

Predictive or condition-based maintenance is a proactive maintenance strategy that allows you to monitor the performance and condition of your machinery in real time. Doing so will enable you to enhance machine reliability and accurately predict when your equipment needs to be maintained —rather than waiting for it to fail. Using a combination of wired or wireless sensors, Internet of Things (IoT), augmented mechanics, machine learning and data analytics, Acoem’s predictive maintenance tools portfolio will help your business anticipate problems before they occur. Schedule maintenance activities at the right time, receive alerts for potential issues with a degree of certainty and enhance your overall industrial productivity.

Reviews

There are no reviews yet.