EAGLE

Wireless diagnostic solution for critical assets

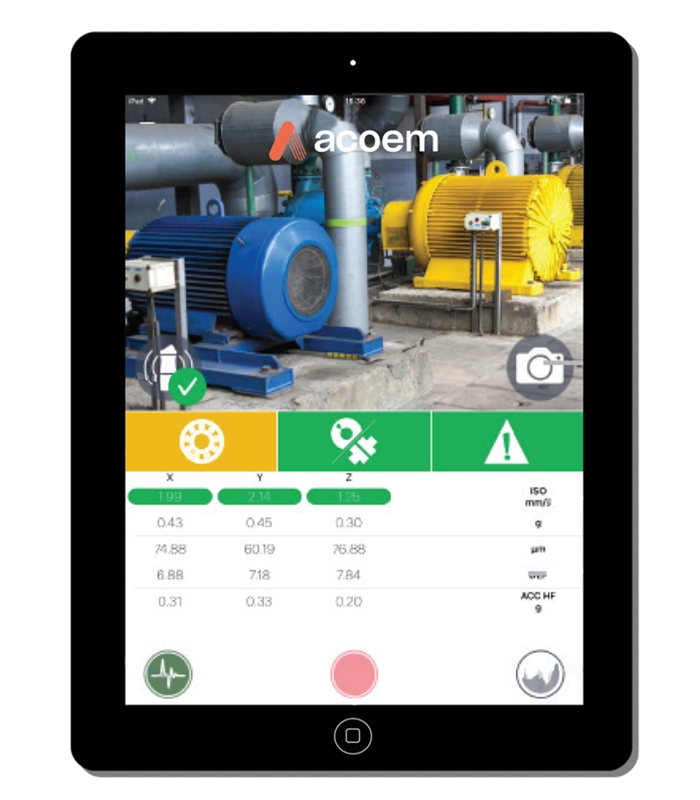

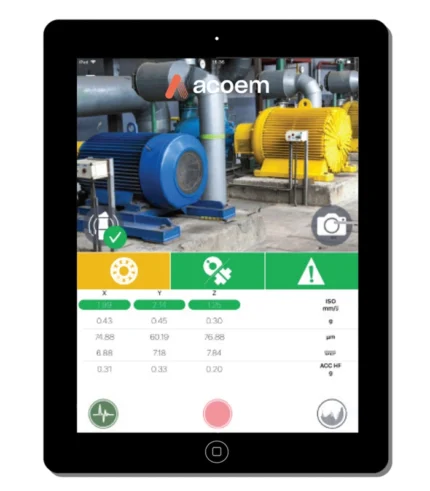

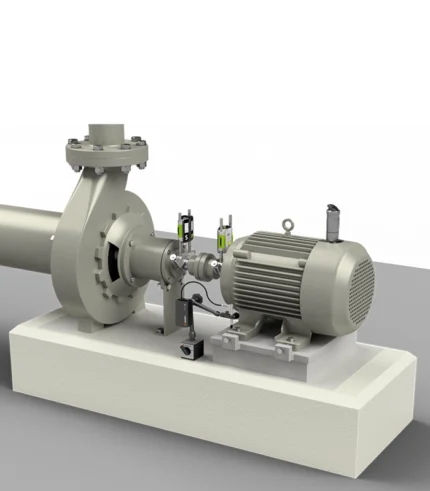

Acoem Eagle’s revolutionary wireless remote diagnostic solution is a true game-changer that safeguards crucial components of your rotating machinery. This cutting-edge technology efficiently detects faults, including bearing and gear defects, ensuring seamless operations and preventing costly setbacks for your business.

One of the key advantages of Acoem Eagle is its all-inclusive data provision. It measures automatically vibration in three directions as well as the bearing temperature, providing comprehensive data at your fingertips. With this information, there’s no need to send personnel on-site for additional measurements when an alarm is triggered. Acoem Eagle empowers you to conduct remote diagnostics effortlessly, right from where you are. Save time, resources, and minimize downtime with the power of Acoem Eagle’s wireless remote diagnostic solution.

Datasheets

Eagle-Brochure_Acoem.pdf Eagle-Tech-Specs_Acoem.pdf

Maximise the reliability of your critical rotating assets

Predictive or condition-based maintenance is a proactive maintenance strategy that allows you to monitor the performance and condition of your machinery in real time. Doing so will enable you to enhance machine reliability and accurately predict when your equipment needs to be maintained —rather than waiting for it to fail. Using a combination of wired or wireless sensors, Internet of Things (IoT), augmented mechanics, machine learning and data analytics, Acoem’s predictive maintenance tools portfolio will help your business anticipate problems before they occur. Schedule maintenance activities at the right time, receive alerts for potential issues with a degree of certainty and enhance your overall industrial productivity.

Reviews

There are no reviews yet.