NESTi 4.0

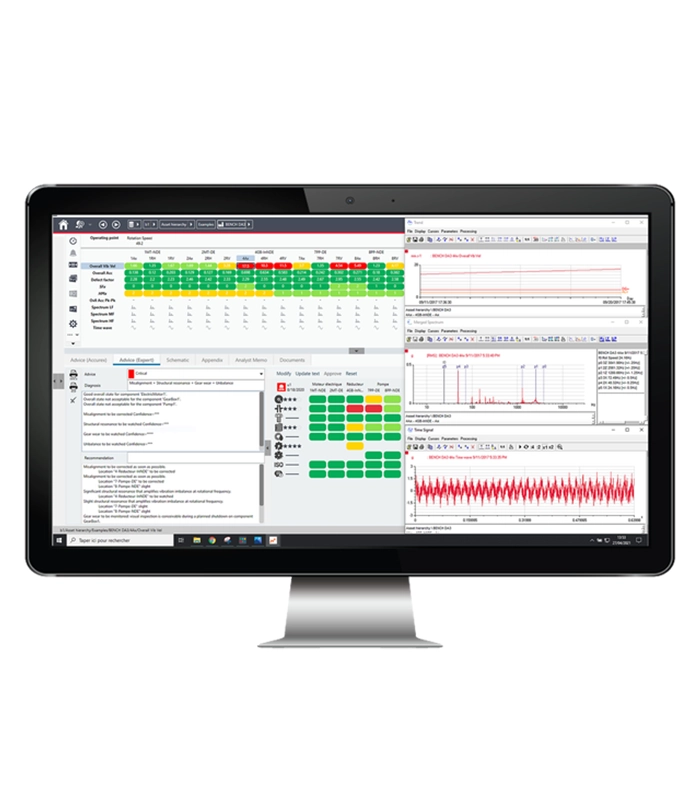

Predictive maintenance software platform

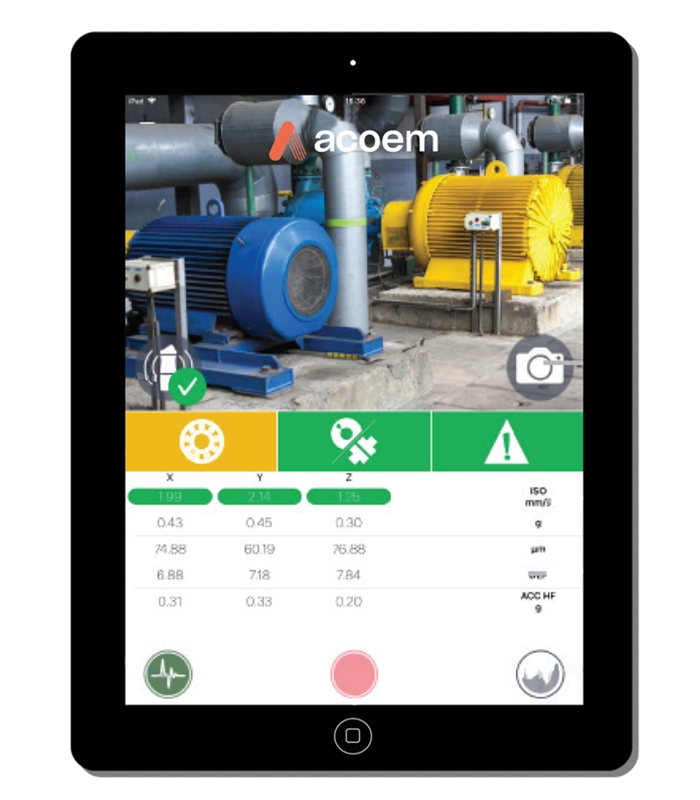

Connect your digital factory with the Nest i4.0 software suite to harness the power of Acoem’s Accurex™ Artificial Intelligence (AI) and create a fully integrated predictive maintenance ecosystem. The only predictive maintenance software you will ever need, NESTi4.0 works seamlessly with Acoem’s signature vibration measurement solutions — the FALCON portable analyser, Machine Defender app, EAGLE wireless sensor and the almighty MV-x real-time monitoring system for precise vibration measurement data and automatic diagnostics.

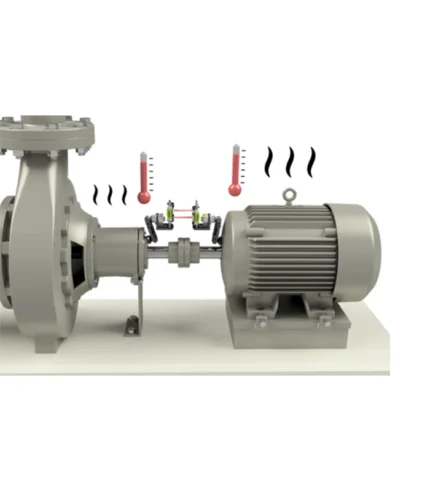

Maximise the reliability of your critical rotating assets

Predictive or condition-based maintenance is a proactive maintenance strategy that allows you to monitor the performance and condition of your machinery in real time. Doing so will enable you to enhance machine reliability and accurately predict when your equipment needs to be maintained —rather than waiting for it to fail. Using a combination of wired or wireless sensors, Internet of Things (IoT), augmented mechanics, machine learning and data analytics, Acoem’s predictive maintenance tools portfolio will help your business anticipate problems before they occur. Schedule maintenance activities at the right time, receive alerts for potential issues with a degree of certainty and enhance your overall industrial productivity.

Reviews

There are no reviews yet.