NESTi 4.0 WebPortal

WebPortal: Next level predictive maintenance

The best just got better

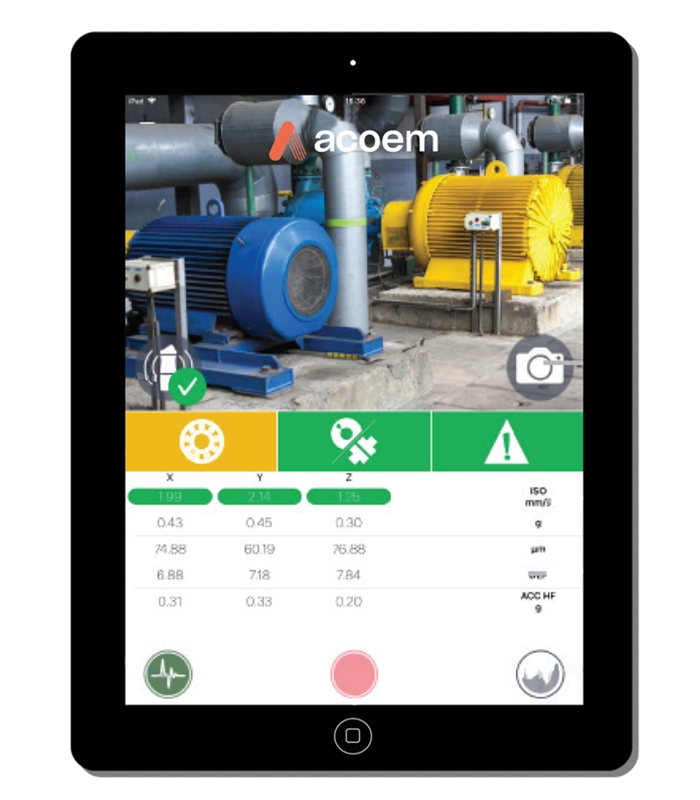

Introducing WebPortal – the newest module in the Acoem Nesti4.0 software platform and your gateway to total machine maintenance management.

Featuring advanced functionality and greater accessibility to your critical assets’ health status, WebPortal is a game changer for the way you connect with and leverage your monitoring data.

WebPortal offers universal supervision over all your monitored rotating assets and every Acoem instrument – the EAGLE, FALCON, MV-x and RT-300 vibration and alignment apps.

So much more than a predictive maintenance dashboard, WebPortal is a fully web-based solution that adapts to your network’s requirements and each user’s needs, providing a customised and holistic overview of your machines operations.

Maximise the reliability of your critical rotating assets

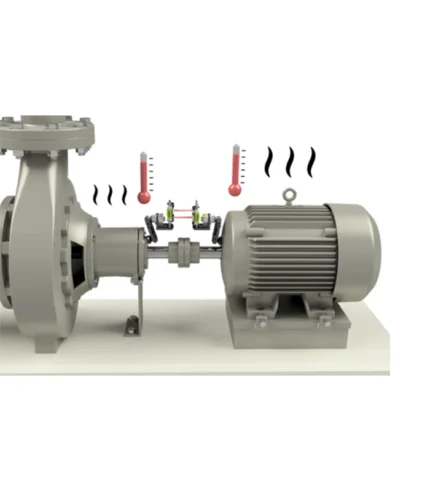

Predictive or condition-based maintenance is a proactive maintenance strategy that allows you to monitor the performance and condition of your machinery in real time. Doing so will enable you to enhance machine reliability and accurately predict when your equipment needs to be maintained —rather than waiting for it to fail. Using a combination of wired or wireless sensors, Internet of Things (IoT), augmented mechanics, machine learning and data analytics, Acoem’s predictive maintenance tools portfolio will help your business anticipate problems before they occur. Schedule maintenance activities at the right time, receive alerts for potential issues with a degree of certainty and enhance your overall industrial productivity.

Reviews

There are no reviews yet.